Area of use

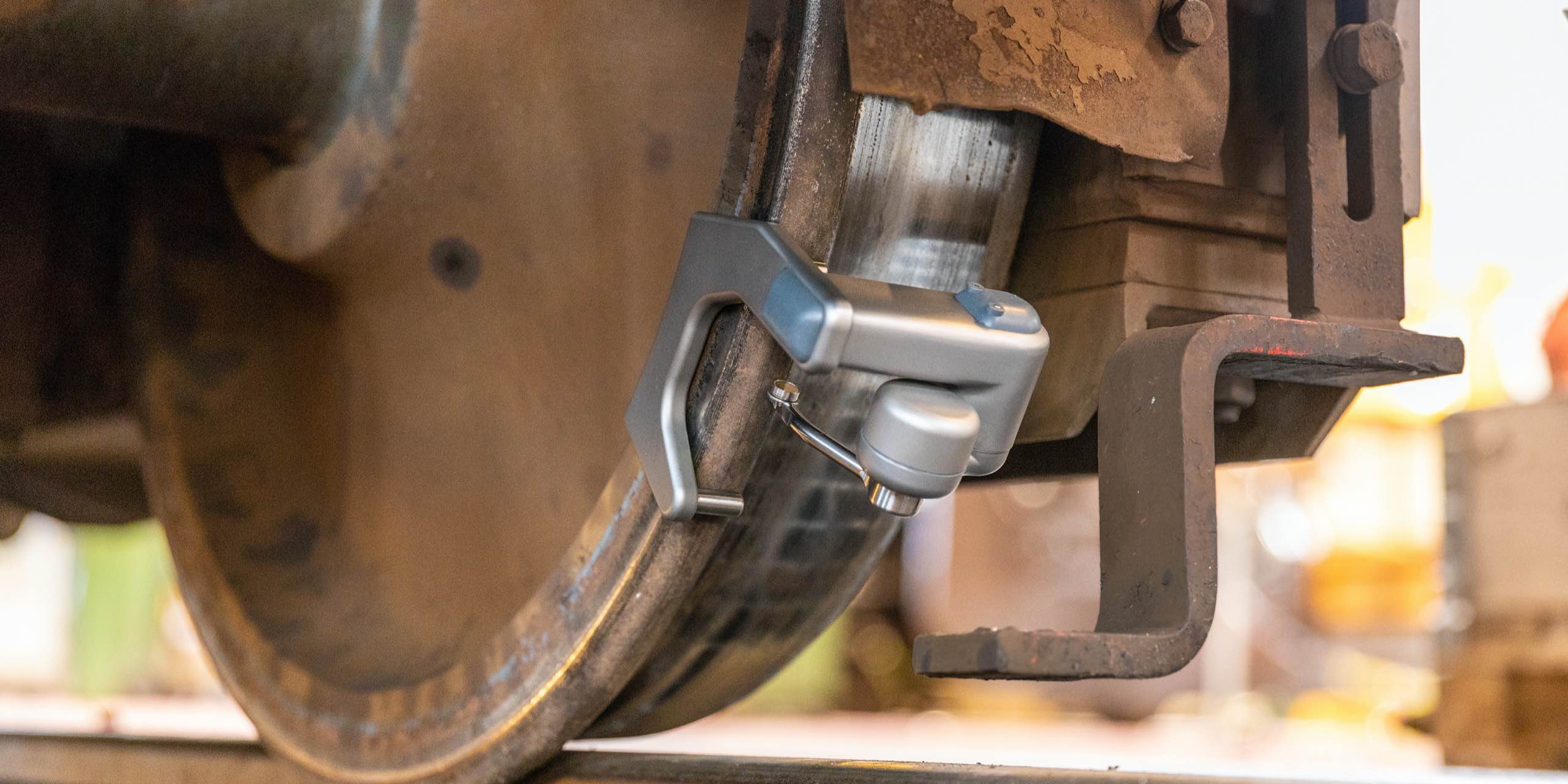

The MiniProf BT system is an excellent full contact measurement system with Bluetooth connection for fast, reliable

and extremely high quality profile measurements. Combined with a user-friendly and flexible software package which

can easily be configured from basic use to in-depth post measurement analysis, MiniProf BT can be used for numerous

purposes on all types of wheel, rail and brake profiles. It enables the user to make critical decisions in purchase,

maintenance, quality and safety departments etc. and represents a great platform for research and development all

over the world.